Computational Platform

Challenges We’re Addressing

PCP/MOF is known as a compatible material with machine learning and molecular simulation, such as material informatics, because of its structure with regularly aligned pores.

Therefore, those methods have been used to predict the optimal PCP/MOF structure and its performance for various applications.

On the other hand, such predictions don’t take feasibility into account in most case.

Even if the structure is predicted to have high performance, it is often impossible to synthesize, or even if it can be synthesized, it is often not stable enough to be practical, or the cost in terms of raw materials and processes is very high.

Thus, PCP/MOF has many attractive properties, but it is not easy to find practical candidates.

Our Technologies

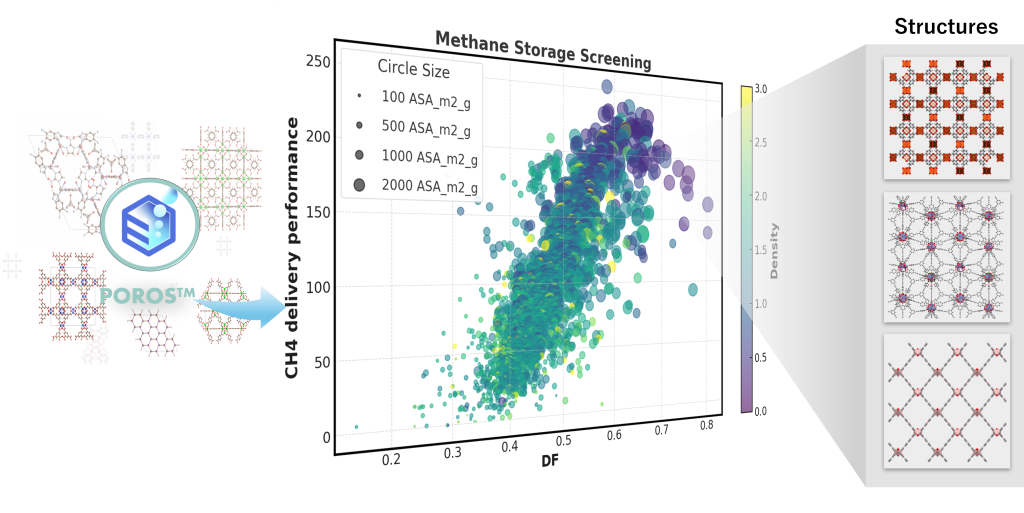

To address the above issues, Atomis has established our proprietary structural database, POROSTM, consisting of more than 100,000 species.

In addition to the huge variety of PCP/MOF, POROSTM incorporates structural data (crystal lattice information, pore size, pore size, crystal density, specific surface area, etc.) and physicochemical stability data for crystalline porous materials such as COF, MOP, zeolite, etc. against water and heat, as well as cost information.

This allows us to make proposals that meet customer needs not only in terms of performance, but also in terms of cost.

In addition to POROSTM, we also focus on computational simulation technology.

For example, with Matlantis, we can perform vibration analysis, kinetic calculations, and reaction path analysis.

We also utilize a variety of other computational tools such as molecular size estimation by mathematical analysis, pore distribution, and adsorption simulation by GCMC.